Services

WHAT WE CAN OFFER YOU

CHEMICAL ANALYSIS

The specified chemical composition of steel, stainless steel and iron alloy products according to their relevant specifications are determined using optical emission spectroscopy (OES) and the analysis at a minimum include the weight percentage C, Si, S, P, Mn, Ni, Cr, Mo, Cu, Al, V, Nb, Ti, Sn, and Sb. The nitrogen (N) and Boron (B) content is determined and reported when requested.

Non-ferrous alloys such as Aluminium (Al), Nickel (Ni), Copper (Cu), Cobalt (Co), Zinc (Zn) and Titanium (Ti) based alloys are also analysed.

Specialised analysis is provided through co-operation agreements and include the following:

- Wet chemical analysis (ICP).

- LECO Carbon and Sulphur.

- Scanning electron microscopy combined with EDS/EDX analysis is used to determine the chemical composition of corrosion products, surface coatings or other deposits.

- Specialist polymer analysis.

- Sophisticated techniques like XRF, XRD, etc are available upon special request.

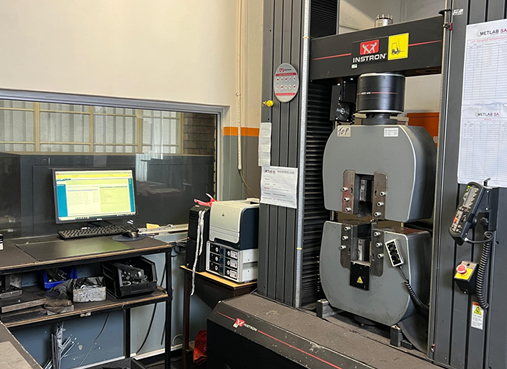

MECHANICAL TESTING, INCLUDING WPS and PQR’s

A dedicated workshop and machine shop, equipped with CNC machines ensure that samples are prepared strictly in accordance with the requirements of material and testing standards and with precise control over dimensions and surface finish.

The testing laboratory boasts a wide range of testing equipment, guaranteeing equipment availability and presentation of test results without delay. Equipment is maintained and calibrated strictly in accordance with the requirements of ISO 17025 and testing standards. Tests are performed according to national (SANS) and internationally recognised standards such as ISO, American (ASTM, ASME, AWS, API), Japanese (JIS) or European (EN, DIN, BS, etc).

Services which can be provided include the following:

- Tensile strength (yield, UTS, elongation and reduction in area).

- Elevated temperature testing (20 – 950°C).

- Through thickness tensile testing (Z test).

- Impact toughness testing (V notch, U notch and Izod) from room temperature down to – 196°C.

- Load testing (tensile and compression).

- Bend testing.

- Bend and re-bend testing of rebars.

- Flattening and flaring tests.

- Welding procedure qualifications and welder certification testing according to ASME, AWS, ISO and other international specifications when required.

- Evaluation of tubesheet welds, including push out testing.

- Fillet fracture.

- Nick breaks.

MATERIAL AND METALLURGICAL TESTING

Assessment of various ferrous and non-ferrous metals, as well as non-metallic products are performed and include the following:

- Macro structure (weld) etching and assessment.

- Metallographic examination of micro

- Microstructure and phase assessment.

- Grain size determination.

- Non-metallic Inclusion assessment.

- Coating thickness and quality determination including galvanizing coating according to SABS 934/935 and ASTM A90.

- Decarburization and carburization depth determination.

- Sulphur printing.

- Determine volume fraction of phases (manual point method).

- Ferritscope measurements.

- Geometry evaluation on rebar.

- Hardness tests (Vickers, Brinell, Rockwell) including 3-point hardness testing for fasteners and hardness traverse.

- Jominy test

NON-DESTRUCTIVE TESTING AND SIMULATED HEAT TREATMENT ON TEST COUPONS

Various non-destructive tests are provided through co-operation agreements on samples prior to preparation and testing and include:

- Magnetic Particle Inspection (MPI).

- Dye penetrant testing.

- X-Ray/ Radiographic.

- Ultrasonic testing (UT).

- Heat treatment processes i.e., pre- and post-weld heat treatment, can be simulated and carried out on test coupons prior to testing.

SPECIALISED SERVICES, FAILURE INVESTIGATIONS AND CONSULTING

Comprehensive Metallurgical investigations into in-service failures or product non-conformances are available as well as assistance with metallurgical quality control.

- Third party witnessing can be arranged.

- Failure Root cause analysis.

- Basic failure investigation.

- Scanning electron microscopy and EDS/EDX analysis of fracture faces, corrosion products or entrapped matter.

CORROSION TESTING

Corrosion properties of materials are verified by performing intergranular corrosion, weight loss and pitting tests to various ASTM and ISO standards.

- Salt spray tests are carried out in accordance with ASTM B117 and ISO 9227.

- Intergranular corrosion in accordance with ASTM A262, ISO 3651-1/2/3

- Detecting intermetallic phase or pitting in duplex stainless steel in accordance with ASTM A923 and ASTM G48

ON-SITE TESTING

Services available for on-site testing include:

- Determining of chemical composition by means of portable OES.

- Hardness testing (Brinell, rebound and UCI).

- Ferrite count (Feritscope).

- Specialised Metallurgical replication.

- Macro etching.